let the wind do its job™

DELTAS™ and

ACTIVE MORPHING

BLADES

FOR WIND TURBINES

Design ExpLoration Tool for Adapting aero-Structures™

SIMPLY PUT,

WHAT THE

CUSTOMER

WANTS

TODAY

reduce fatigue loads to increase turbine efficiency and lifetime and drive down the levelized cost of energy

Longer blades drive lower energy cost...so far

the blade is the most influential component of a wind turbine for energy production

yet longer blades

exert greater loading on the structure and blade design must expand the operational range of the wind turbine to increase power generation without creating other problems

bigger means optimized designs are a must

the old paradigm...rigid blades...will not serve the customer

the new paradigm:

a uniquely optimized blade that boosts efficiency and supports the global trend of increasing size and scale of offshore wind turbine systems.

Atrevida Science's

Active Morphing Blades™

with a flexible, aerodynamic design that morphs to achieve optimal shape as wind speed changes.

There are places out in the world, at sea, where winds tend to blow harder and more uniformly above sea level than on land. And these higher wind speeds with low turbulence produce more energy.

Our Value Proposition is greatest in these places of huge wind resources…Atrevida Science’s Active Morphing Blade™

With 80% of U.S. electricity demand located in coastal states and total offshore wind energy technical potential (2,056 Gigawatts) equal to about double the nation’s demand for electricity, offshore wind energy has the potential to contribute significantly to a clean, affordable,

and secure national energy mix.

National Offshore Wind Strategy; Facilitating the Development of the Offshore Wind Industry in the United States

Why Offshore?

Global Offshore Wind Market Set to

Grow Sixfold by 2030

Customer discovery demonstrated wind energy, the largest new green energy, has two major pain points: efficiency (energy production) and failure (maintenance). The cost of wind energy is a significant factor to grow market share. Driving the cost down is accomplished through design innovation that improves wind turbine efficiency and overall system reliability. These drivers are affected by blade design. According to Sandia National Laboratory, the current blade design prevents wind turbines from being used to full potential. Hence, the Department of Energy and the International Energy Agency both emphasize the need for novel rotor design.

During customer discovery, Atrevida Science reached out to experts from the wind industry such as Mikkel Kristensen, the Senior Vice President of Offshore Engineering at Siemens Gamesa (ranked first among the world’s wind turbine manufacturers), Michael Bergey, president of Bergey Wind Power, and Jason Jonkman from the National Renewable Energy Laboratory. All of these individuals agree there is a need for active morphing blades that can adapt their shape to optimal geometry according to wind conditions. Such a blade realizes increased efficiency and sheds loads that are deleterious to the system.

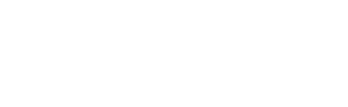

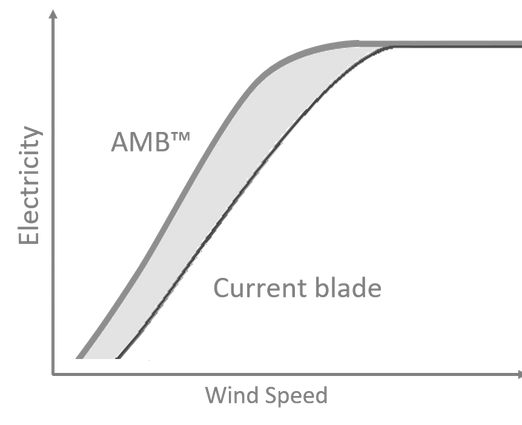

Sandia determined that morphing blades could increase the production of a 1.5 MW wind turbine by 11% and reduce fatigue loads by 70%. Moreover, these loads result in instability issues for floating wind turbines –at a time when the industry is shifting to offshore wind farms!

Atrevida Science is developing active morphing blades™ (AMB™) for wind turbines to target these issues. The AMB™ morphs through actuation to achieve optimal shape as wind speed changes. Atrevida Science's AMB™ design offers three main value propositions: efficiency increase (up to 14%, every 1% means 5% return on investment), load reduction (means less maintenance and greater savings in installation costs of up to $95k), and improved stability.

Improving aerodynamic performance across the board for:

Offshore Wind

Onshore Wind

Aerospace